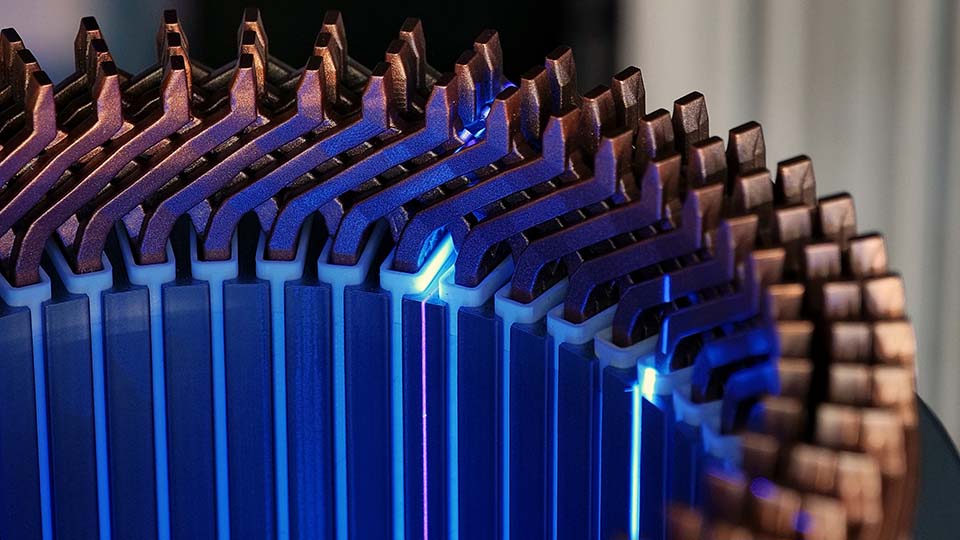

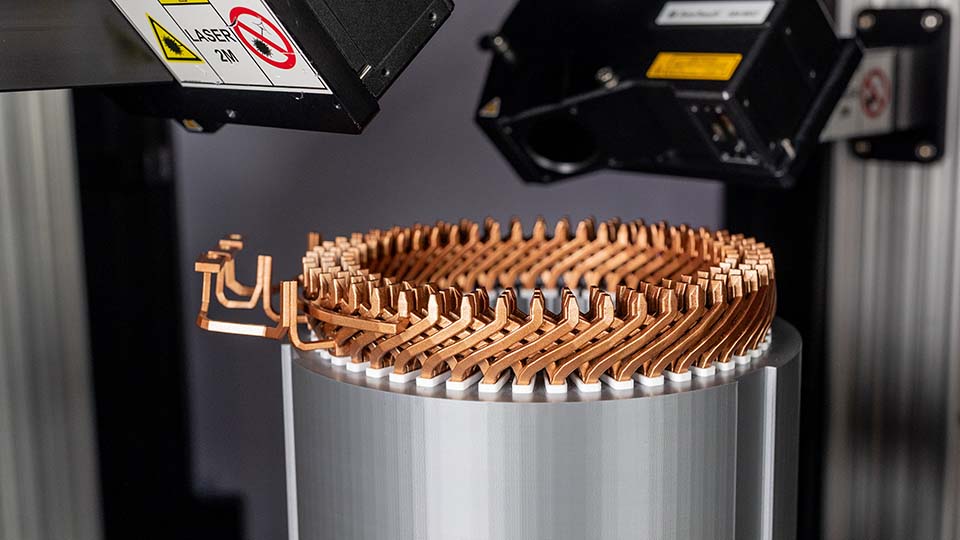

The ZeroTouch® EV solution suite is our latest innovation in electric vehicle stator measurement technology.

ZeroTouch® achieves reliable and repeatable measurement by 3D referencing over the complete reference surfaces. Collecting millions of data points minimizes surface local defects or roughness, making the machine extremely repeatable even when measuring closely positioned hairpins.

Configurable for manual and automatic part load and unload, ZeroTouch® can be installed in the immediate vicinity of the production line to improve production throughputs.

Performing scan cycle times from 30 seconds - 1 minute per part, ZeroTouch® optimizes production processes by detecting and avoiding production deviation through real time measurements, allowing adjustment of upstream processes to reduce waste.

| Dimensions | |

|---|---|

| Measurable Envelope Max. (Diameter x Length) | 425 mm x 300 mm (16.7 in x 11.8 in) |

| Part Outer Diameter Max. | 425 mm (16.7 in) |

| Part Length Max. | 375 mm (14.8 in) |

| Payload Weight Max. | 65 kg (143.3 lbs) |

| Inner Diameter (typical) | 120 mm (4.7 in) |

| System | |

| Dimensions (W x D x H) | 1,150 mm x 1,550 mm x 2,805 mm (42.25 in x 61.0 in x 110.5 in) |

| Weight | 2,000 kg (4,400 lbs) |

| Environment | |

| Temperature (Transport/Storage) | 15°C (59°F) to 40°C (104°F) |

| Temperature (Operational) | 18°C (64.4°F) to 22°C (71.6°F) |

| Software | |

| HMI Operating System | Windows |

| System Control | ZeroTouch® Orchestrator |

| Metrology Analysis | ZeroTouch® Analysis Package |