ZeroTouch launches the ZT-EV solution suite for electric vehicle stator measurement, enhancing quality assurance and efficiency through advanced gauging technology and real-time data integration.

ZeroTouch's new headquarters in Tualatin, Oregon, aims to enhance smart, sustainable manufacturing by delivering innovative automated metrology solutions and real-time data to elevate industry efficiency and resilience.

ZeroTouch is proud to announce it has been awarded the Ford Technical Excellence Award for its work in 3D In-Process & Finished Stator Inspection Using Laser Line Sensors for measurement of hairpin and stator assemblies for EV Motors.

ZeroTouch has partnered with Hexagon Manufacturing Intelligence to enhance precision manufacturing in Europe by delivering advanced, non-contact, high-speed gauging technology for real-time process quality and efficiency.

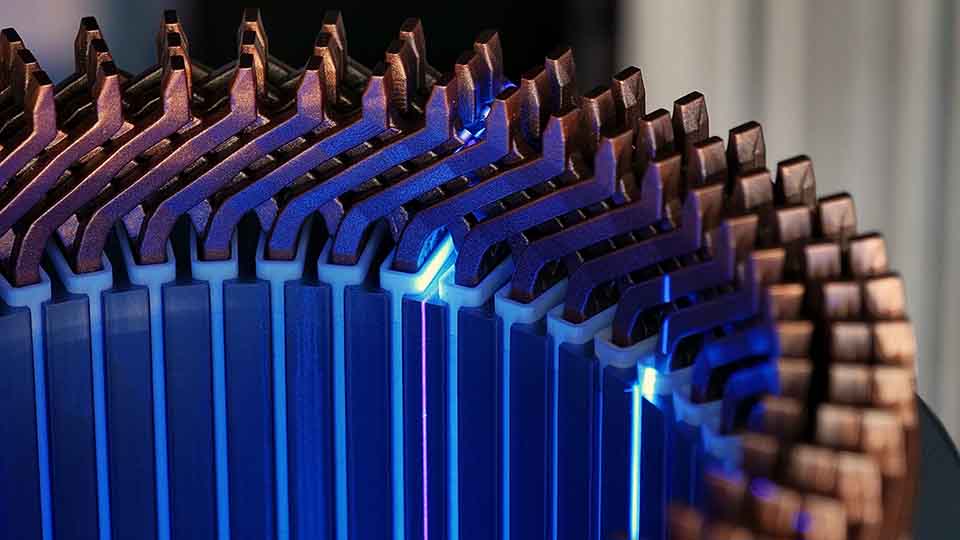

Electric drives consist of a fixed stator and a moving rotor. In order to achieve optimum drive performance and low wear, both components must be matched to each other with well under millimeter precision, so accurate conformity control is of immense importance.

In-line Measuring Platform Creates Comprehensive 3D Model of Brake Discs within 20 Seconds and Detects Micron-level Surface Defects.

Sandvik has announced the official launch of a new player entering the industrial metrology space. ZeroTouch will specialize in delivering advanced automated industrial measurement solutions.

ZeroTouch Metrology, a global provider of high-precision inspection and metrology solutions for advanced manufacturing, has announced it will be demonstrating new capabilities on the ZeroTouch Rotational Metrology Platform at the 2025 Control Show in Stuttgart (Hall 9 / Booth 9202).

ZTR is a precise, high-speed inspection system for processing automotive components faster than traditional methods.

Metrology plays a crucial role in precision manufacturing, ensuring components meet exact specifications and tolerances

Brake discs are among the safety-relevant components in a vehicle and must withstand several million braking operations without damage.

A precise, high-speed metrology and inspection system for processing automotive transmission parts faster than traditional methods.