ZeroTouch® family of high-speed, non-contact, in-line and near-line metrology, and inspection platforms for complex geometry parts such as stators/rotors, brake discs, gears, and medical implants.

ZeroTouch® proudly presents the ZT-EV solution suite—our latest advancement in electric vehicle stator measurement.

ZeroTouch delivers the premier in-shop floor gauging by combining non-contact laser scanning and comprehensive inspection analysis to automate inspection of precision components, delivering superior accuracy to meet challenging GR&R requirements, measuring geometric features, and generating a digital twin at each stage of production with a dense, micron-level point cloud.

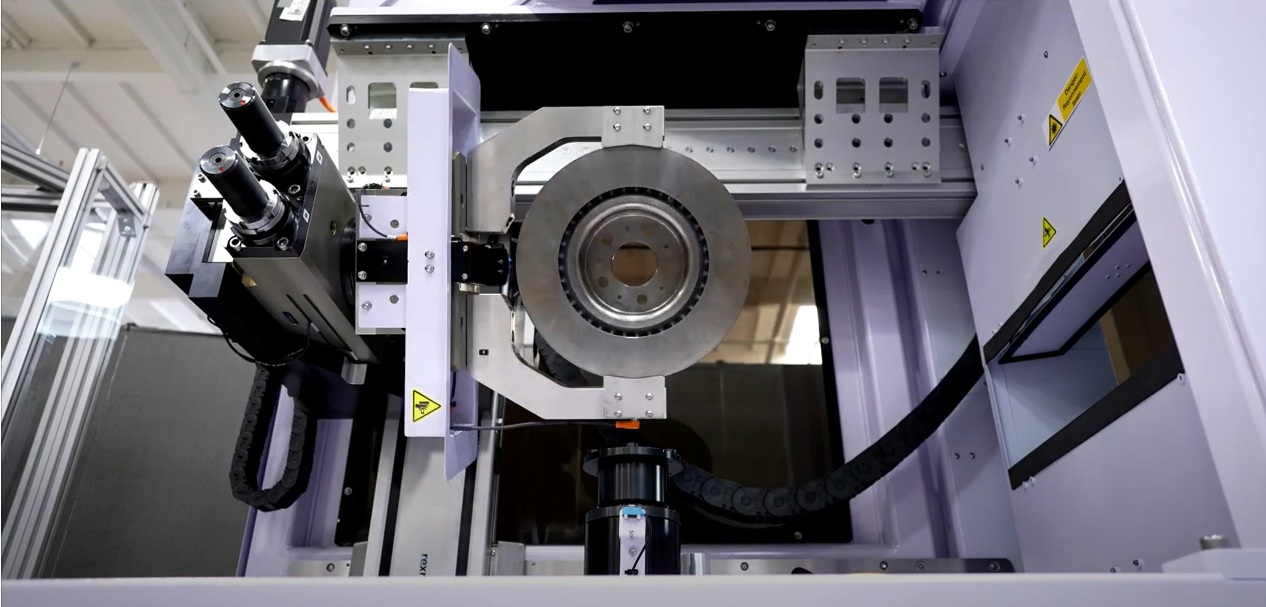

ZeroTouch ZTR delivers fast inspection times by fully digitizing a part such as automotive brakes, rotor/stator components, emotor assemblies, and complex, shiny geometries such a medical orthopaedic knee inserts.

The fastest inspection times are achieved by ZeroTouch ZTL, which can move a single part of the pallet of pieces across an inspection path of multiple lasers with sub-10-second cycle times. Comprehensive analysis combined with automation options delivers CMM-type inspection reports in cycle for every piece.

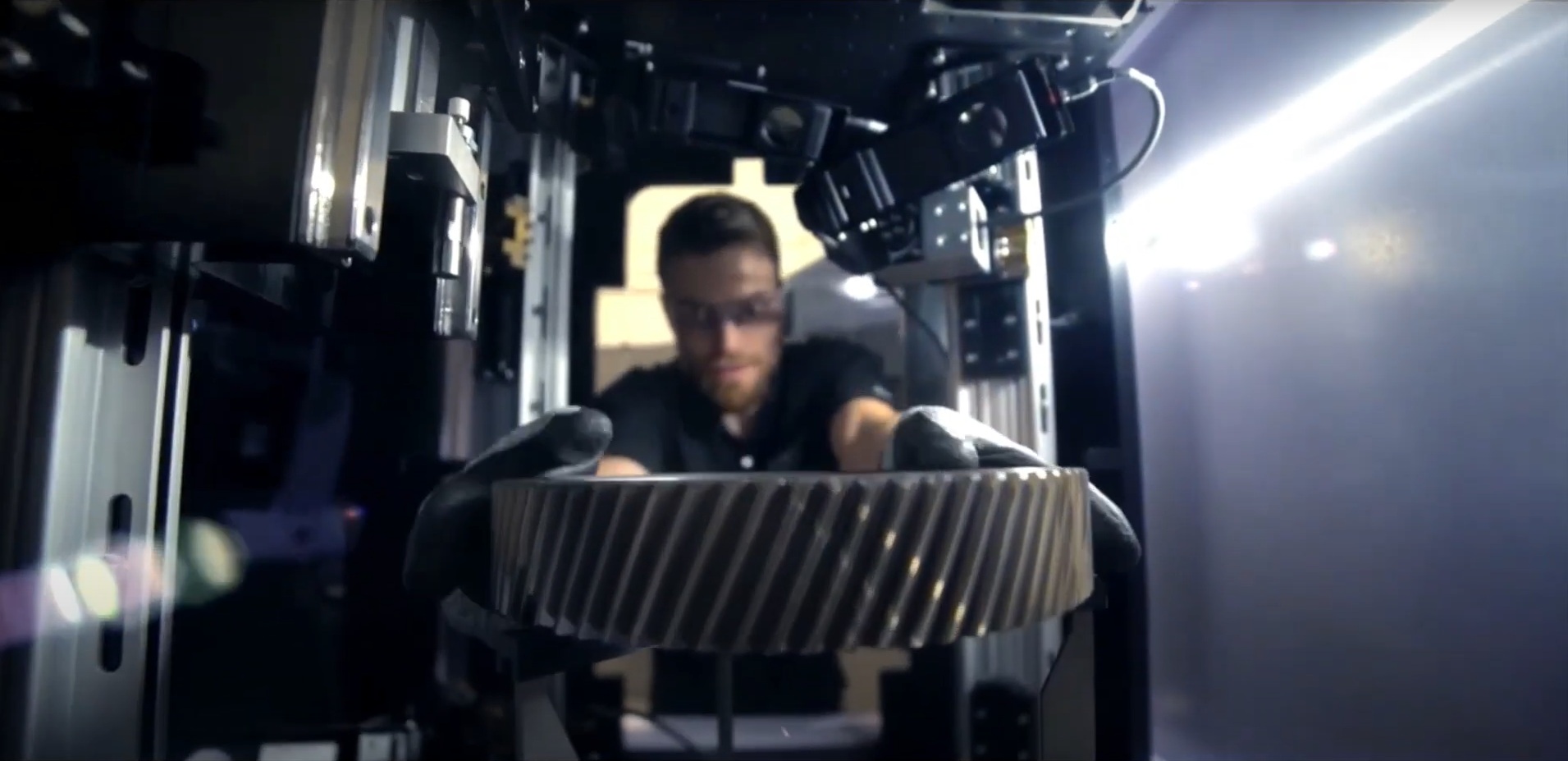

100% 3D inspection system for high-volume gear manufacturing, cutting, and hobbing operations delivers immediate process feedback. Suited for final part inspection as well as rough pre-heat treat operations. ZeroTouch ZTG delivers comprehensive gear inspection in-station, real-time, without the need for a trip to the gear lab for offline inspection.

The ZeroTouch® family of gage solutions removes knowledge bottlenecks from the manufacturing process. ZeroTouch® performs rapid in-line or near-line measurements with high precision and repeatability. Multiple laser sensors capture millions of data points and evaluate in cycle, providing instant process feedback to ensure optimum dimensional quality.

Key benefits include:

Rapid Inspection Cycles: Complete inspections in just seconds, ensuring high throughput suitable for in-line and near-line applications. This means your production line can maintain a steady flow without downtime.

Real-Time Results & Analysis: Enabling rapid decision-making and immediate feedback to the production process.

Comprehensive Analysis & Defect Detection: Achieve comprehensive quality assurance in one measurement, identifying defects and ensuring accuracy.

Surface Versatility: Part coating is not required to capture shiny surfaces, allowing for flexibility in measuring diverse materials.

Automatic Load for In-Line Deployment: Configurable system adapts to needs, supporting a wide range of part dimensions and weights.

Compact Design: The small footprint optimizes production space, allowing for easy integration into existing processes.

Comprehensive Digital Twin: Dense point cloud enables comprehensive insights into every part.

Key Applications: Blades, Vanes

Non-contact measurement systems are invaluable in the aerospace industry, where precision is critical. These systems excel in measuring the complex geometries of blades and vanes without risking deformation, essential for maintaining the integrity of high-performance components. Their ability to perform rapid measurements ensures that production schedules remain on track without compromising quality.

Key Applications: Rotors, Stators, Brakes

In the automotive sector, especially with the rise of e-mobility, non-contact systems provide the precision needed for complex die castings and fuel injectors. These systems can handle large-volume inspections of moving parts, ensuring every component meets the rigorous standards required for efficient engine performance and safety.

Key Applications: Orthopedic Knee implants, Hip stems, Bone plates

The medical device industry benefits significantly from non-contact measurement's ability to profile delicate surfaces like orthopedic implants and bone plates. The systems ensure these critical components are measured accurately without physical contact, preserving their integrity and ensuring they meet exacting medical standards.

Key Applications: Watches, Drills, Cutting Tool Inserts

Where the tiniest defect can lead to significant issues, ZeroTouch provides real-time monitoring and feedback, allowing immediate defect detection and drive corrective actions, enhancing the quality and reliability of products whilst maintaining the high standards required in mass production environments.